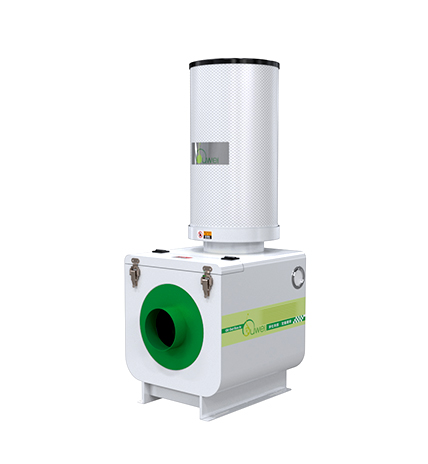

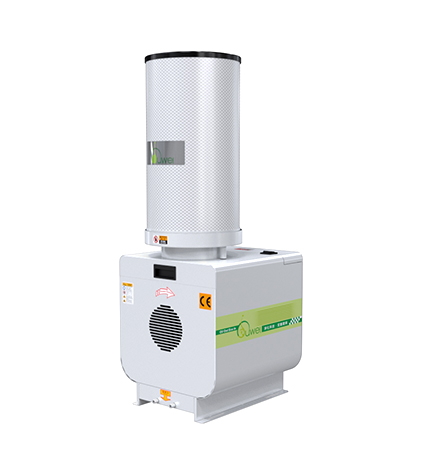

JW-003-R oil mist extractor with 99.9% oil mist collection and purification efficiency has passed CE certification and is the best choice for CNC machine mist extraction for many machine tool manufacturers in the EU!

This CNC mist extractor's stainless steel mesh designed by the 3D impact principle provides the best oil mist interception effect, and the turbo impeller has strong centrifugal wind suction and achieves excellent oil separation performance.

The collected oil mist does not require further filtration and can be directly reused, it not only effectively improves the air quality in the workplace, but also has the characteristics of high efficiency, energy saving and environmental protection.

Our same-color oil mist collector can be manufactured to match the appearance of the customer's machine. Welcome inquiry!

Principles of Oil Mist Extraction Technology

Environmental Impact of Oil Mist Extraction Technology

- Reducing Air Pollution Oil mist extraction technology effectively removes oil mist from the air, reducing pollution to the atmosphere and contributing to improved air quality, thus protecting the natural environment.

- Resource Conservation

- Increased Production Efficiency A clean working environment contributes to higher employee efficiency, reduces safety hazards during the production process, and ultimately enhances overall production efficiency.

- Compliance with Environmental Regulations In many countries, environmental regulations impose strict requirements on pollution emissions during industrial manufacturing processes. The application of oil mist extraction technology helps companies comply with these regulations, demonstrating a commitment to environmental responsibility.

Applications of Oil Mist Extraction Technology

- Metal Processing Industry Oil mist extraction technology finds widespread application in metal cutting, grinding, milling, and other processing operations. By utilizing efficient oil mist collection devices, ensures a clean working environment and enhances production efficiency.

- Mechanical Manufacturing Industry In the mechanical manufacturing sector, the operation of various machine tools can also generate significant amounts of oil mist. The application of oil mist extraction technology can be employed to address oil mist emissions, effectively reducing adverse effects on machine tool operations.

- Automotive Manufacturing Industry The cutting fluids and cooling liquids used in the automotive manufacturing process can also produce oil mist. Applying oil mist extraction technology ensures that workers on automotive production lines have a clean and safe working environment.

- Aerospace Industry In aerospace manufacturing, where high-precision metal cutting and processing are common, the generation of microscopic oil mist is more likely. The application of oil mist extraction technology in this field helps ensure a pristine and uncontaminated production process.

| Item | Unit | Specification |

|---|---|---|

| HP | HP | 1.5HP 1.12KW |

| Air flow | m3/min | 26 |

| Air intake diameter | m/m | 150 |

| Voltage | V | 220/380 |

| Electric cuttent | A | 4.5/2.6 |

| Cycle | HZ | 50/60 |

| Speed | R.P.M | 2850/3500 |

| Noise | db | 70 |

| Weight | kg | 53 |

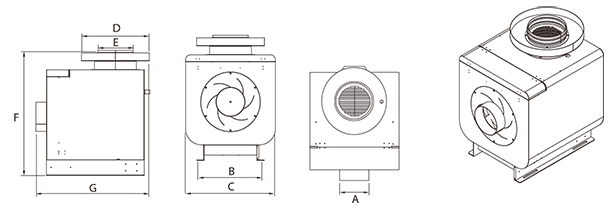

| Item | Size |

|---|---|

| A | 146 |

| B | 308 |

| C | 450 |

| D | 340 |

| E | 178 |

| F | 626.2 |

| G | 568.4 |

-

Stainless Net

Stainless Net -

PVC Tube Hose

PVC Tube Hose -

Wire

Wire -

PVC Flexible Duct Hose

PVC Flexible Duct Hose -

Hose Clamp

Hose Clamp -

Rubber Feet

Rubber Feet -

Flange

Flange -

Motor Starter

Motor Starter

Adjustable Hose

Adjustable Hose Ozone Machine

Ozone Machine Adjustable Stand

Adjustable Stand

Principles of Oil Mist Extraction Technology

Environmental Impact of Oil Mist Extraction Technology

- Reducing Air Pollution Oil mist extraction technology effectively removes oil mist from the air, reducing pollution to the atmosphere and contributing to improved air quality, thus protecting the natural environment.

- Resource Conservation

- Increased Production Efficiency A clean working environment contributes to higher employee efficiency, reduces safety hazards during the production process, and ultimately enhances overall production efficiency.

- Compliance with Environmental Regulations In many countries, environmental regulations impose strict requirements on pollution emissions during industrial manufacturing processes. The application of oil mist extraction technology helps companies comply with these regulations, demonstrating a commitment to environmental responsibility.

Applications of Oil Mist Extraction Technology

- Metal Processing Industry Oil mist extraction technology finds widespread application in metal cutting, grinding, milling, and other processing operations. By utilizing efficient oil mist collection devices, ensures a clean working environment and enhances production efficiency.

- Mechanical Manufacturing Industry In the mechanical manufacturing sector, the operation of various machine tools can also generate significant amounts of oil mist. The application of oil mist extraction technology can be employed to address oil mist emissions, effectively reducing adverse effects on machine tool operations.

- Automotive Manufacturing Industry The cutting fluids and cooling liquids used in the automotive manufacturing process can also produce oil mist. Applying oil mist extraction technology ensures that workers on automotive production lines have a clean and safe working environment.

- Aerospace Industry In aerospace manufacturing, where high-precision metal cutting and processing are common, the generation of microscopic oil mist is more likely. The application of oil mist extraction technology in this field helps ensure a pristine and uncontaminated production process.