Why Install a CNC Mist Collector in CNC Machine?

CNC machine tools release a lot of oil mist, coolant mist, smoke and fume when they are working. These potentially dangerous airborne particles may cause harm to employees. When employees are in this environment for a long time, it is easy to develop health problems and a CNC mist collector can collect and purify these harmful substances and reduce pollutants in the air. Therefore, the CNC mist collector has become one of the indispensable pieces of equipment in modern factories.

How is CNC Oil Mist Formed?

CNC oil mist and oil smoke are formed when the rotating tools in the machine come into contact with metalworking fluids such as coolants and lubricants when rotating rapidly. These liquids will evaporate during the processing, producing tiny oil mist droplets which are released into the air.

What Impact Does Oil Mist Have on Human Health and Machines?

The oil mist formed by CNC machining can be large or small. Larger oil mist may be inhaled into the nose and trachea causing rhinitis, bronchitis, etc, and health problems. Smaller oil mist can settle in the lungs and cause considerable irritation to the eyes, nose and throat. Besides, when oil mist falls on the factory floor, it may cause the risk of workers slipping.

For machines, CNC oil mist may cause damage to the machine, thereby increasing maintenance costs.

How Does CNC Machine Mist Collector Work?

What Are The Benefits of Oil Mist Collectors for CNC Machines?

- Effectively reduce maintenance costs and downtime.

- Improve air quality, protect employees' health

- Environmentally friendly

Oil mist or oil fume is often released during metal processing, these substances will affect the internal parts of the CNC machine. The oil mist collector for CNC machines can effectively solve this problem, through CNC machine mist collectors remove particles and oil in the air, can reduce the damage to CNC machine parts reduce the cost of maintenance and downtime, and increase production efficiency.

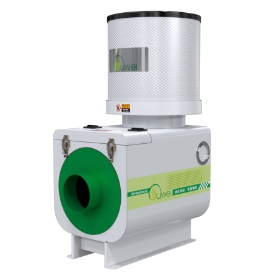

Juwei provides oil mist collectors for CNC machines to adopt an innovative air filter system uniquely designed to remove oil mist and smoke from the air which collects up to 70% filtration and then returns pure air back into the working area to protect the health of employees.

CNC mist collectors help reduce carbon emissions in metalworking and the collected oil mist can be recycled and reused without harming the environment.

In summary, there are many benefits to installing CNC mist collectors, so find Juwei Machinery to invest in oil mist collectors for your CNC machine now!

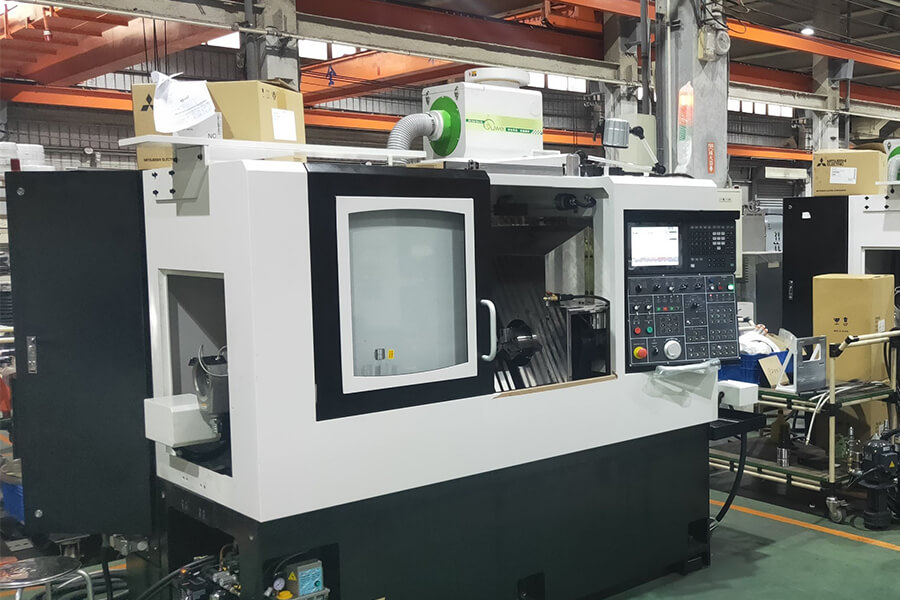

CNC Machine Oil Mist Collectors Solutions

When purchasing an CNC mist collector, you need to consider the type of machine to be installed, the size and capacity of the oil mist recovery machine, maintenance requirements and cost, you can contact Juwei, the CNC mist collector provided by Juwei can be directly installed on the CNC machine so minimizing installation costs, highly stable filtration system is designed for maximum efficiency with low vibration and noise so it will not interfere with the operation of the machine it is attached to.

Click to view which brands have installed Juwei oil mist collectors!