What is the Oil Mist Collection System (Oil Mist Air Cleaner)?

Oil mist collection and filtration systems are innovative air filter methods uniquely designed to remove oil mist or oil smoke in the air that is given off when metalworking fluids are used to cool or lubricate parts and tools during the metalworking process and collect the recovered oil for reuse. Juwei is an oil mist collector systems manufacturer from Taiwan, we provide a mist collector and filtration system that incorporates a 3D impact process that collects up to 70% of oil mist molecules from the incoming air for reuse. Further filtration then returns pure air back into the working area.

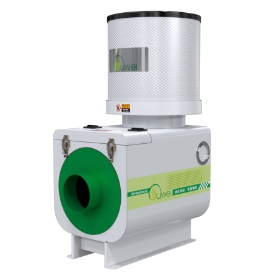

The oil mist collector and filtration system unit is designed to conveniently mount to existing machinery minimizing installation costs. This highly stable filtration system is designed for maximum efficiency with low vibration and noise so it will not interfere with the operation of the machine it is attached to. The unique, high-speed impeller process provides a high suction, the centrifugal cyclone that achieves the best oil rejection. Further filtration steps then purify the air. Juwei oil mist collector (air cleaner) advanced air purification technology provides filtration efficiency as high as 99.95%~99.995%.

How does an oil mist collection system work?

Initial Filtration - Iron Chip and Particle Screening

The oil mist collector begins its operation with an initial layer of filtration, consisting of a stainless-steel woven mesh strategically placed at the interface between the machine equipment and the oil mist recovery collection system. This stainless-steel mesh acts as a protective barrier, effectively preventing iron chips and other impurities from infiltrating the air purification system. This crucial first step ensures that iron chips or any foreign particles do not disrupt or harm the oil mist recovery collection machine. Approximately 70% of the remaining oil mist proceeds to the subsequent filtration stages. Importantly, the stainless-steel mesh is designed for easy disassembly, cleaning, and reuse, offering convenient maintenance and significant cost savings on consumables.

Cyclone Filtration

As air is drawn into the oil mist collector, a specially engineered centrifugal fan impeller generates a unique cyclone effect, greatly enhancing the efficiency of oil collection. During its passage through the next filtration stage, this cyclonic action generates static electricity, further aiding in the adsorption of oil mist onto the stainless-steel woven mesh.

Efficient Oil Separation and Collection

The third stage incorporates a large screen with an expanded surface area to optimize oil recovery efficiency. Specifically designed, this filter screen employs a cyclone flow pattern to ensure exceptional filtering performance.

Centrifugal Filtration

In the fourth stage, a high-speed centrifugal impeller is employed to create a powerful suction cyclone that compels oil mist to adhere to the inner wall of the filter. The intercepted oil mist is efficiently collected by internal oil baffles.

HEPA Filtration

The final stage of filtration utilizes a barrel-type HEPA filter. With the majority of oil and larger particles already removed by the preceding four stages, the HEPA filter excels at capturing any remaining sub-micron mist and smoke particles. This results in the delivery of highly purified air back into the working environment.

300mm and 600mm Cartridge Filters

Juwei provides HEPA cartridge filters in two sizes; a 300mm barrel filter and a 600mm cartridge filter which can be purchased according to your needs. For light machining processes that only give off coolant mist, oil mist and water vapor, you can choose a 300mm barrel filter. For machining processes that involve heavy-duty cutting, where high temperatures may produce oil smoke or fumes, a 600mm barrel filter will be required to properly remove oil smoke particles.

The 600mm HEPA cartridge filter can also be used for applications where only water vapor and oil mist are given off, allowing for longer operating times between filter changes. If you are unclear about which barrel filter will be best suitable for your machining processes, please contact us and we will be glad to help you make the right choice.

Oil Mist Collection Filtration

Use 3D Impact Principle

The 3D impact principle is a unique professional design of Juwei. The principle uses a thick filter of various grades of woven, stainless-steel fibers. These fibers create irregular collisions that help oil mist adhere to the filter. Oil droplets gradually accumulate and are returned to the machine. This stainless-steel filter mesh can be easily cleaned to extend the service life of the filtration system.

Pleated Filter Material

Juwei uses circular pleated filter material to increase the filtration area and improve the filtration efficiency.

HEPA Air Purifying Filter

Machining processes can often generate very fine particles or smoke which can only be removed by a highly efficient HEPA filter. To ensure the air returned to the working environment is of excellent quality, the final stage of the Juwei Oil Mist Recovery Air Purifier is a barrel-type HEPA filter. The HEPA barrel filter conforms to the European H13 standard. With an efficiency rating of 99,97% for 0.3 µm particles, this final HEPA filter returns highly pure air back into the working area.

Depending on the working environment, HEPA filters of varying efficiencies are available to choose from. The HEPA filter barrel is designed to screen out particles larger than 0.3 µm, with an efficiency of 99.99%.

The Juwei Oil Mist Air Purifier uses HEPA EU-H13 grade filter material, which conforms to the European EN1882 specifications. It has a filtration efficiency of 99.95%~99.9995% or more for MPPS. (Most Penetrating Particle Size) An optional activated carbon filter is available to absorb odors and further enhance air purification.

Filtering Efficiency

Oil mist recovery of up to 70%

The first stage of the system is a woven stainless steel mesh. In addition to effectively preventing iron chips from entering the air duct hose. In addition, some of the oil recovered at this stage is allowed to flow directly back to the machining work area. Removing a large percentage of debris and oil in the first stage will increase the efficiency, speed, and service life of the following stages.

Recovery Efficiency

Up to 70% of oil mist and processing fluid will be recovered by the filter system. Up to 95% of this recovered oil and fluid can be reused in the machining processes. In actual on-site testing, the filter system has been able to filter out more than 99.5% of oil mist.

Even during times when the factory’s machine tools are not in operation, running the Juwei Oil Mist Recovery Air Purifier will improve the quality of ambient air in the factory.

-V1.jpg)